Manufacturing dished ends since 1895

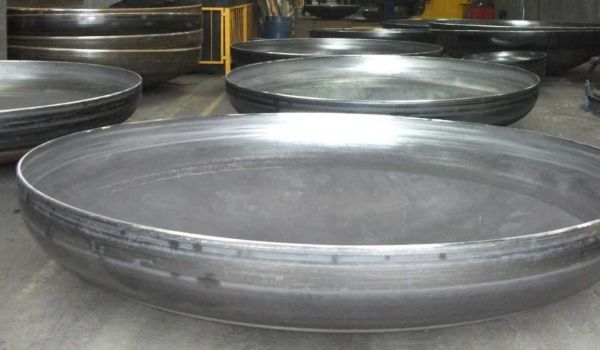

LBBC Beechwood has been manufacturing dished and flanged ends at our Stanningley site since 1895.

During that time we have acquired a wealth of experience and expertise. There can be very few applications that we have not come across, and we would be more than pleased to give advice on any specific design or application you may have.

Dished and flanged ends are cold formed by firstly pressing the spherical radius followed by spinning the corner radius and straight flange. They can also be dished only (pressed), flanged only (spun) or conical spinning’s.

Torispherical, ellipsoidal and hemispherical heads

We are able to manufacture torispherical, ellipsoidal and hemispherical heads by either pressing or spinning or a combination of both, in a range of materials including carbon steel, stainless steels, titanium and aluminium.

We can also machine secondary features which may be required after the forming process has been completed.

Additional processes include; polishing, heat treatment , shot blasting and painting as well as pickle and passivation for non-ferrous materials .