Five Generations of Pickards

David Pickard

Herbert Pickard

Mourice Pickard

David Pickard

Howard Pickard

The Story so far..

1800’s

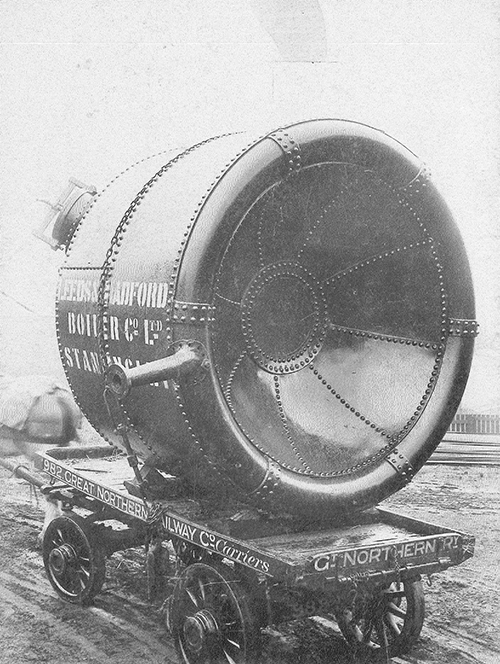

- The Leeds and Bradford Boiler Company was Founded by Mr. D. Midgley in 1876 to manufacture boilers for local crane suppliers, tar stills and brewing pans for local pubs.

- Company was bought by Mr. R.S. Dower, Mr. D. Pickard and Mr. J. Brodie in 1892 after the company faced cash flow difficulties.

- Mr. R.S. Dower’s daughter Ellen married Mr. David Pickard’s son, Herbert.

- Herbert Pickard was appointed Managing Director and gradually purchased further shares to give the Pickard family a majority shareholding.

1900’s

- New management continued with boiler operations and branched out to specialise in tar stills and tar distillation plants to facilitate the building of the world’s first tar roads.

- The demand for mines during the First World War led to the company’s first presswork operations with hemispheres hot pressed and supplied to Japan and Turkey.

1920’s and 1930’s

- Times are hard as the Leeds and Bradford Boiler Company faced strong competition from UK boiler makers and the country experienced depression, fuel shortages and strikes.

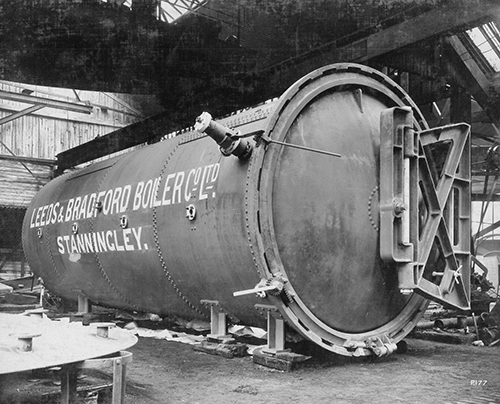

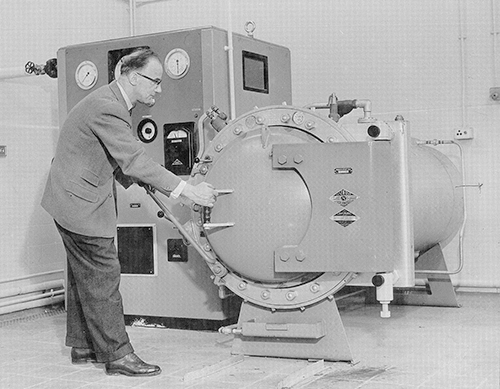

- Maurice Pickard gave the Leeds and Bradford Boiler Company a unique competitive advantage through his invention of the revolutionary Quicklock® door in 1934.

- The company subsequently specialised in manufacturing autoclaves that incorporated the Quicklock® door. The design was an instant success since it required minimal effort compared with heavy swing bolt alternatives.

- Maurice pioneered many safety interlocks that led him to be consulted by the Health & Safety body to set the mandatory standards that are still present today.

1940’s and 1950’s

- After the destruction on World War 2, LBBC helped Britain to re-equip the world with capital plant.

- The main product line was now supplying autoclaves with applications from vulcanising to timber impregnators and textile steamers.

- The Leeds and Bradford Boiler Company supplied the textiles, building, rubber and food industries across the globe.

1960’s

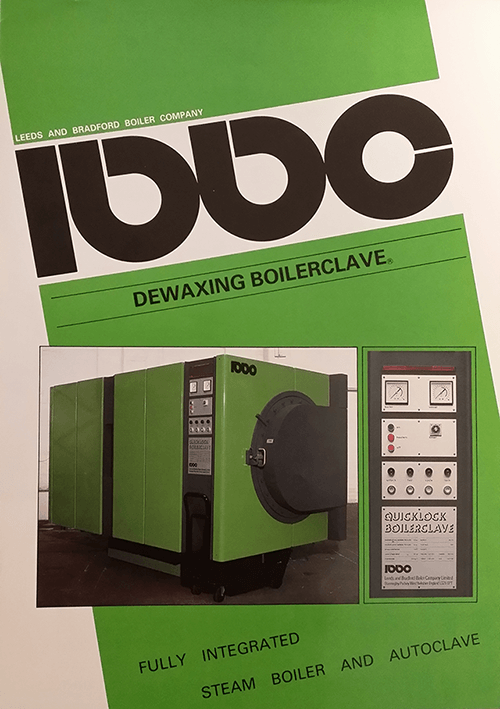

- The company expanded into the investment casting/lost wax process, which was relatively new as a mainstream foundry process.

- During the boom times The Nestle Company was LBBC’s largest customer with over 200 vessels produced.

- LBBC was supplying autoclaves to over 100 countries.

- The company was awarded The Queens Award for Exports in 1967 presented by the High Sheriff of Yorkshire.

- The company heavily invested in extending the factory and purchasing new production equipment including upgrading the dished end equipment to a full range of cold pressing and spinning machines.

1970’s

- As traditional industries declined, LBBC responded to the changes in the marketplace by developing a sub-contract machining division and developing its revolutionary autoclave systems.

- The Boilerclave®, Leaching Autoclave and Thermoclave® revolutionised process technology within the investment casting and advanced composite curing industries.

- The Boilerclave® is still recognised globally as the market leader.

1980’S AND 1990’S

- As with many engineering manufacturers at the time, the 1980’s proved tough as Britain’s recent boom times came to an end and developing countries became more competitive.

- The lack of debt and quality products ensured the company’s survival through the period.

2000’s

- The company split into two business divisions in 2003.

- LBBC Technologies to concentrate on the development, supply and support of the technology based equipment.

- LBBC Beechwood to focus on the manufacturing activities of fabrication, machining and dished end pressing.